India can be termed to be one of the world’s manufacturing superpowers with a rich portfolio of products running from textiles to electronics, as well as many more. Among all those sectors where the Indian manufacturing sector has seen massive growth, one is the production of packing products, particularly the stretch films. Stretch films are popular across most industries due to their cost efficiency, flexibility, and ability to safeguard products stored or transported in warehouses. These reasons have shot the demand for stretch films not only locally but also internationally.

This blog will outline India as one of the premier stretch film producing countries and discuss its potential globally, the rise in importance of exports, as well as how companies like Flexibond Tapes fit in with the new demand for sustainability in packaging solutions.

Growing Need for Stretch Films

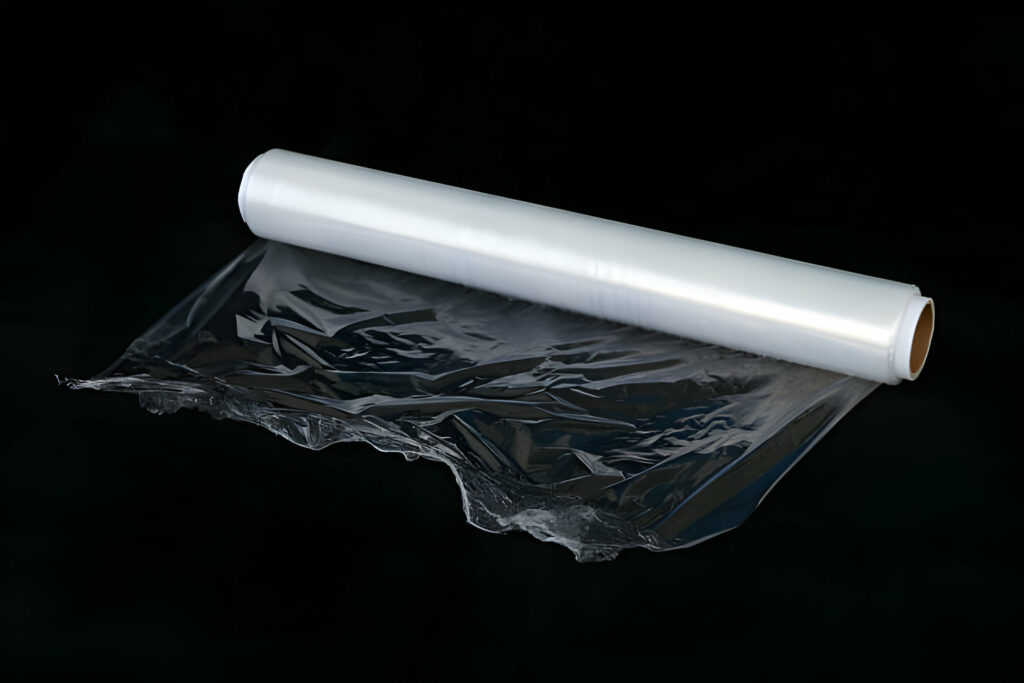

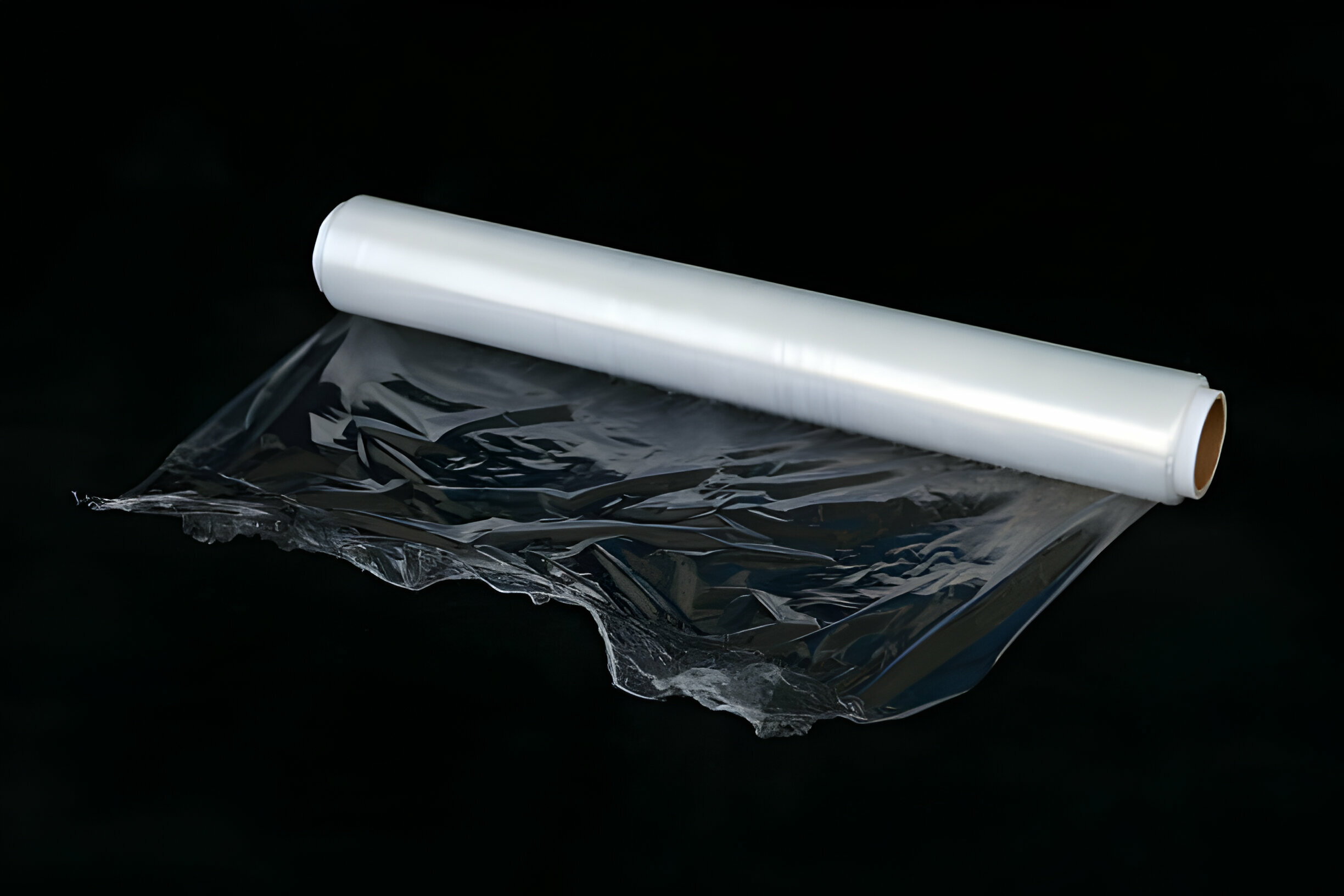

Stretch films have become very widely used to secure commodities or palletized loads in transit, thus ensuring goods are safe from damage during shipment. The material has a plastic film with high levels of stretchability that clings closely to the products it wraps around in order to protect them from dust, moisture, and tampering. There is, hence a need for stretch films in a variety of industries that include manufacturing, logistics, retail, food, and e-commerce.

The growth drivers for the demand of stretch films are rising global trade. As the connectivity increases globally, consumers begin demanding safe products. Packaging has become a vital part of the supply chain. Several benefits make stretch films very popular: tough, user-friendly, and inexpensive. Flexibility is one of the factors adding value to the increase in demand for stretch films. These films can be found in various strengths and thicknesses and types, so that businesses can select the correct solution for their particular requirements.

Other than the practical advantages, stretch films improve safety and security, particularly in the industries of logistics and retailing. In e-commerce, products are moved long distances, and stretch films ensure little breakage during handling and delivery. As the business of e-commerce grows, there will be a tremendous increase in demand for these materials, including stretch films.

India Leading Stretch Film Producer

India is known to be a manufacturing sector whose output is at best good quality but affordable. The stretch film manufacturing industry in India has experienced growth in the past few decades. More people have become industrialized, there are more export markets, and there is a middle class with increased purchasing power.

One of the global largest producers of plastic materials, India is a country that appropriately caters to the demand for stretch films worldwide. The country has extensively developed various manufacturing units equipped with state-of-the-art technology to produce numerous varieties of stretch films for manufacturers. Thus, Indian manufacturers can manufacture stretch films matching international quality standards and meet the demands of different sectors—from food and beverages packaging to industrial applications.

Innovation and continuous improvement are the other major characteristics of the Indian stretch film manufacturing industry. Indian companies in this sector always strive to improve performance through newer technologies, formulation improvements of products, and finding sustainable packaging solutions. Keeping these at the core has helped India to remain competitive in the global market now surfacing their focus on eco-friendly materials.

Flexibond Tapes has been emerged as a prominent stretch film manufacturing company all over India. Given its vast knowledge in the business, the group has earned significant popularity with excellent performing stretch films that are supposed to give immense stretchability with good load retention while at the same time offer sufficient protection. Their applications cut across logistics companies, pharmaceutical industries, e-commerce companies, among others. Due to its commitment towards high-quality production of packaging material, the company is the most trusted name in the industry in India and worldwide.

Emerging Export Potential for India

Stretch film demand in the world has always been in a rising curve. The Indian destination has quickly turned into a ground for sourcing among manufacturing houses which are eager to source packaging material at relatively affordable prices. This has allowed India-based manufacturers of stretch film to export this with the added benefit of supplying superior quality product offerings at a lesser price than producers elsewhere. The cost advantage coupled with the nations’ huge capacity for manufacturing make India the best supplier for any kind of stretch films across the various industries.

The export potential of Indian manufacturers in the stretch film market is supplemented by firm trade ties with North America, Europe, the Middle East, and Southeast Asia. Strategically sited and having a powerful logisitcal infrastructure, manufacturing companies from here can easily deliver speedily and efficiently to international clients, which is of paramount importance in industries like e-commerce.

Indian manufacturers in the recent past are witnessing good growth for stretch films exports. Middle East, for example, is increasingly sourcing packaging material from India as the product quality is very good and costs much lower. The corresponding outcome is that stretch film manufacturers are witnessing good orders emanating from the European and North American market where low-cost qualitative packaging solution is required.

Adaptability to international standards is the most important factor behind the success of Indian manufacturers in the export market. Indian manufacturers of stretch film have constantly updated their production systems in such a way as to meet global quality certifications, such as ISO standards, in line with securing export deals. Indian companies are increasingly interested in sustainability, so they come up with environment-friendly stretch films that can answer the growing international market demand for sustainable packaging solutions.

As e-commerce and global trade are on an ever-increasing spree, the manufacturers of stretch films in India find themselves in the most opportune position to snatch larger shares within the global stretch film market. Combining low cost with products of high value, along with focus on the element of sustainability, India has set up to do good well into the international scene.

Stretch Film Manufacturing for Sustainability

Increased environmental consciousness among consumers and businesses has made sustainability the buzzword in the packaging industry. Given that plastic waste is one of the most pressing environmental concerns today, companies worldwide are focusing on green alternatives for packaging materials. Efforts in reducing packaging waste by more sustainable stretch film options include biodegradable and recyclable stretch films developed by Indian manufacturers.

Manufacturers such as the Flexibond Tapes leads this change in using recycled materials in developing the stretch films and, through innovations, have produced stretch films to compete with leading stretch films across the globe, having been innovating other possible alternative materials while perhaps not ensuring the same or comparable protection of the product that can be competitively offered among other stretch film brands, being better for the environment.

Indian manufacturing is focused not only on the development of eco-friendly materials but also in the fight to enhance the efficiency of the overall production process of such companies. Companies can reduce their carbon footprint through efficiency in waste reduction, optimal consumption of energy, and reduced costs of the products. This can prove to be helpful to the environment and can control the costs of a company so that it may increase efficiency at the production line.

With sustainability fast becoming an imperative consideration for all kinds of businesses and consumers, Indian stretch film manufacturers will be expected to carry on the trend of innovation in packaging solutions corresponding with the increasing demands for alternative sustainable products. Such commitment to sustainability is likely to help India expand its export opportunity in this area, as overseas buyers are increasingly looking out for sustainable packaging materials for their products.

Obstacles to the Stretch Film Manufacturing Industry in India

The growth in the stretch film manufacturing in India is fast, yet the challenges that the manufacturers face, to fully capitalize on increased demand for packaging materials are manifold. One of the biggest hindrances is a volatile price for raw materials, including plastic resins. Raw materials can be extremely volatile and have a bearing on the overall cost of production. Manufacturers will find it hard to maintain constant pricing and profitability.

The other challenges are competition from other countries, especially China. China is one of the major players in the international stretch film market. Chinese manufacturers are mostly benefited by a price advantage due to low labor costs and economies of scale. In this regard, Indian manufacturers have to focus more on issues of quality problems in the products to be introduced with advanced technology and even offer far-superior customer service.

Infrastructure and logistics are the challenges that Indian packaging industry faces. Indian has developed logistics to a very large extent. Still, in many areas, especially in the rural and far-flung places, improvement is needed. So, Indian manufacturers have to develop their transportation system and supply chain management for clients.

Despite all these challenges, the future of India’s stretch film manufacturing industry is still optimistic. Focusing on quality, innovation, and sustainability, Indian manufacturers are ready to face competition in the global market and to take advantage of the increasing demand for packaging solutions.

Conclusion

The country is one of the fastest-growing stretch film manufacturing industries in the world, given the growing demand for packaging materials and competitive manufacturing capabilities. As the global packaging market continues to expand, India is poised to become a significant exporter of stretch films. Companies like Flexibond Tapes are leading the charge, offering high-quality, sustainable packaging solutions to businesses across the globe.

It has been cost-effective production, good quality products, and emphasis on sustainability that has made India a very attractive source for stretch films. The ever-increasing demand for packaging materials will necessitate Indian manufacturers’ focus on innovation and efficiency in the global market.

Flexibond Tapes offers all stretch film solutions from reliable, cost-effective, and eco-friendly packaging solutions. To learn more about what’s available in the range of packaging solutions, please call us today. We are here to help you find the right packaging solution for your products, so they are properly protected and secure in transport and storage.