Packaging serves as the backbone of every shipping or warehousing process. The primary use of packaging materials is to protect commodities from harmful agents during transportation, stabilize an item, and ensure that commodities are protected against natural attacks in the form of dust, dirt, or moisture. With different kinds of packaging products and techniques in existence, there is always a missing essential thing: a strapping patti. Strapping patti is generally a strong band or tape that secures goods firmly, thereby providing safety, and making sure nothing inside gets damaged. Let’s discuss why strapping patti is a crucial component for safe and sound packaging, its benefits, and how it contributes to the efficiency of industries globally.

What is Strapping Patti?

Strapping patti, which is tape or band for bundling goods tightly onto pallets, boxes, and containers, generally comes in different kinds of materials, such as polypropylene, polyester, and steel, with different strengths and flexibility. They typically hold goods in place in storage or during transport without sliding out, falling over, or any other potential type of damage. Strapping is part of packaging, and it strengthens a load during shipment over long distances or over tough terrains.

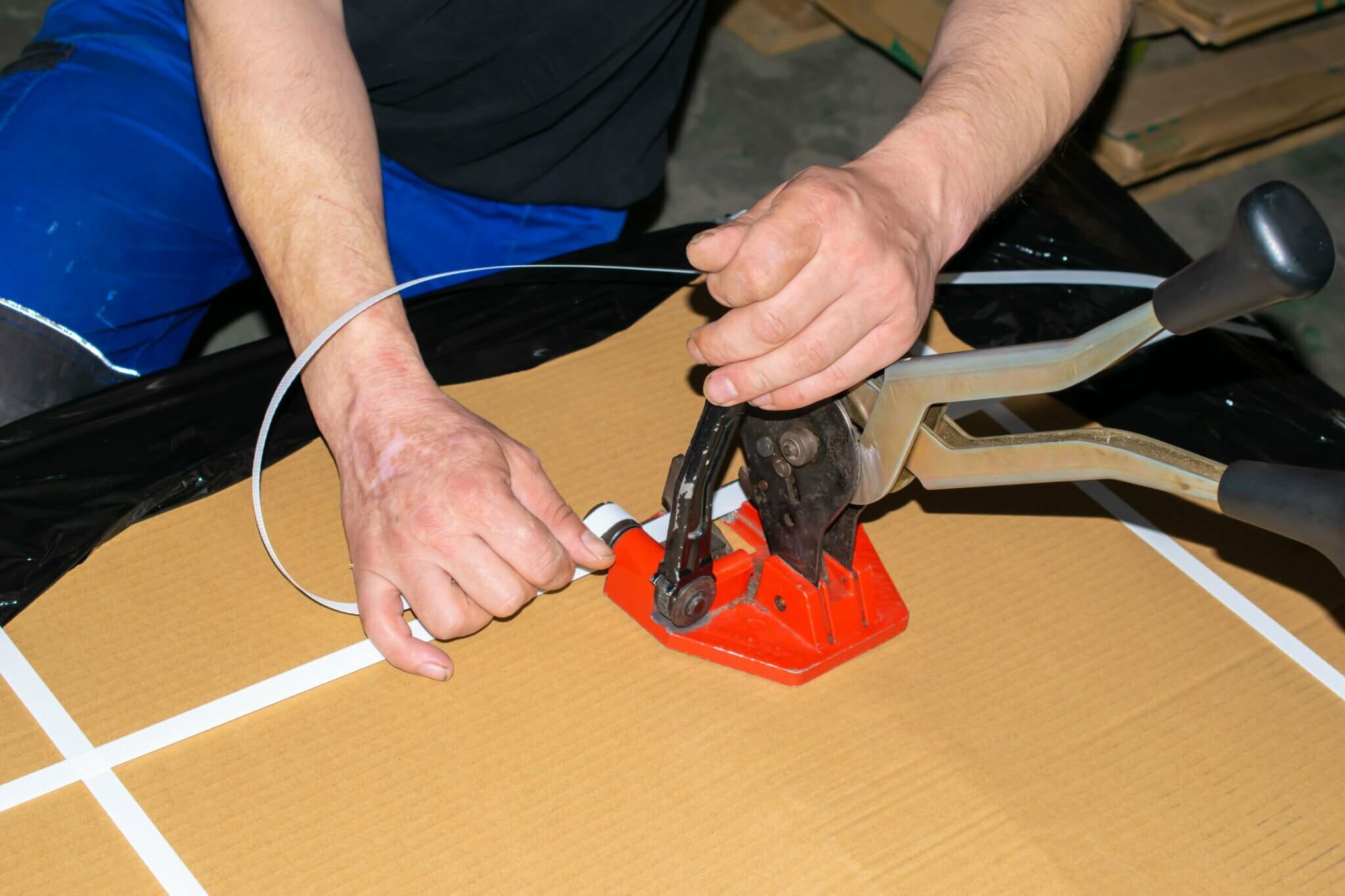

Hand tools or automatic machines can be used to apply strapping. The use of steel strapping is often seen for heavier loads since it is strong. Polyester and polypropylene are applied to medium to low-weight applications because they are light. The flexible nature of the strapping allows the strapped goods to fit together snugly, and they will stay securely packed.

The Role of Strapping Patti in Safe Packaging

Prevents movement and damage as it travels; one of the biggest challenges is that a product will end up moving all over the place, which is happening during transit, shifting items in a box caused by product misalignment leading to damage during shipping. By using strapping around the patti, products would be kept really tight together reducing movement as in transit. Fragile or easy-to-damage items such as electronics, glassware, or other delicate items are especially fragile and require additional care.

Without proper strapping, products sometimes get jostled, leaving scratch marks and dents among other breakages, especially while bumping at turns or fall during handling. Strapping creates added safety on the part such that each will be in a single place in giving assurance on the items which are inside one package to ensure the same ends as when those items were placed.

Improves Load Stability Whether it is a stack of various packages or a pallet load with different items, a load needs to be stable to be moved safely. Adding strength and integrity to the load using strapping patti prevents the load from toppling over or moving around as it’s being moved. In construction, automotive, shipping industries, it ensures that goods are well straped, thereby making it safe and easy to move large and bulky shipments.

When items are not strapped rightly, even slight jolt is enough to create movement of products, which results in spills or damage or an accident. A strap binds loads together tightly. Therefore, it ensures that all the package does not move away, and instead, it moves or gets stacked safely.

It enhances the safety of the workers and handlers. The packaging and transportation are concerned with the safety factors of the employees who handle the products. With strapping patti, packages are easy to handle. Handling massive, heavy, or oblong-sized products can be cumbersome, and without adequate packaging, they become a threat to the safety of the workers when being packed in and unloaded from the vehicles.

Strapping prevents or holds up the products placed onto or within the means of handling, preventing them from sliding or falling. This is very important when handling things that are too large or too heavy to be moved manually by a single person. Through load stability, strapping lowers the chances of accidents, injuries, and product losses as handling becomes much more efficient and safe.

Economically and Efficient Packing Solution Strapping patti provides an inexpensive method to several industries with a view of packaging optimization. As compared to the other options such as shrink wrapping or crate sizing, strapping is cost-effective and also very easy to apply. Materials for strapping are lightweight. Thus, there will not be a great addition in the weight of packaged items that will indirectly save the total shipping costs.

In addition, strapping solutions can be available for automated machines. Therefore, packaging work can be minimized with fewer manual labor efforts, and this process may speed up. Most manufacturers prefer strapping because of its relatively low cost, ease of use, and security to pack items without using expensive packaging materials.

It safeguards from external environmental factors like moisture, dust, and dirt, without letting harmful materials come into contact with the packaged goods. Although strapping may not be waterproof at all, strapping of packaged goods prevents damage to the contents resulting from environmental factors that could harm the transported goods.

It shall be used, in combination with other protective materials such as plastic film or shrink wrap, with strapping packaging where the material is sensitive and perishable-like food or pharmaceutical products-for greater protection against damage from the environment.

Flexibility in Application The above is one of the significant advantages of strapping patti-the application is very diverse. In both logistics and manufacturing industries, strapping is applied to hold goods for different sectors ranging from automotive, electronics, textile to consumer goods.

Second, aside from being versatile in its material, strapping is very accommodating to any packaging arrangement as well. In fact, this is used to secure different products such as a box and a pallet to peculiarly shaped commodities. This aspect of application has been the root cause of its preference in diverse industries for the securing of packages.

Importance of getting the right Strapping Patti Manufacturer

The right strapping patti manufacturer is crucial to ensure that the products you package are safely secured. A good strapping patti manufacturer provides high-quality materials that can withstand the stresses of transportation and handling, ensuring that the packaging remains intact throughout the entire journey.

It is always better to obtain suppliers who are aware of the specific needs of your industry and provide a wide range of materials to choose from. The strapping sourced from such suppliers, which equips you with strong and performing strapping, will ultimately determine how safe your goods are. An experienced and reputed Strapping Patti Manufacturer in India can provide your required or light-duty or heavy-duty strapping solutions.

Flexibond Tapes and Contribution towards Safe Packaging

Flexibond Tapes is one of the leading companies in the industry of packaging with superior quality adhesive tapes and strapping materials. For businesses who are looking for secure packaging solutions, Flexibond Tapes is a very reliable brand as it ensures that the products offered are durable and perform well. Their strapping patti is engineered to offer maximum strength for the protection of your products throughout transit.

With different materials and custom solutions, Flexibond Tapes helps businesses find the perfect strapping solution to their specific needs. From polypropylene to polyester or even steel strapping, the product ensures the necessary strength and flexibility to keep goods secure.

Sustainable Strapping Aspect Patti

As environmental concerns continue to grow, sustainability has become an important consideration in packaging. Traditionally, packaging material is plastic and wood, and both may be causes of environmental degradation; hence businesses look for other more sustainable alternatives. Among strapping patti, polypropylene strapping patti is one of the environmentally friendly options because they are recyclable. The companies using the sustainable strapping solutions will help in their reduction of carbon footprint while still keeping the safety and integrity of the products.

Businesses can achieve sustainability goals and attract green-conscious consumers who prefer environmentally friendly practices by using recyclable and eco-friendly strapping materials. In this context, strapping patti becomes an integral part of the sustainable packaging solutions.

Strapping Patti in Line with Industry Standards

In many such industries, regulatory guidelines for safety in packaging form the basis; however, that aside, whatever it is–export, transit, or factory shipment–this product is all the more pertinent as it does assist companies fulfill standards. Now, the security and stability guaranteed by strapping patti also render it utterly necessary in a package.

For instance, for shipping and logistics, packaging exported goods requires many regulations. This strapping serves to ensure compliance with all safety standards that prohibit damage when over long distances during transport. Also, in an industry such as food processing and pharmaceuticals, strapping offers hygiene and safety by holding them tightly secured inside their packages.

Conclusion: Lock Your Packaging In Place With Strapping Patti Solutions

Strapping patti is one of the key elements in the safe and secure packaging process. Whether it is to avoid damage, stability during load, or meeting industry regulations, strapping is an essential solution for packaging. It encompasses cost-effectiveness, safety, versatility, and strength that make strapping patti a critical tool to ensure goods arrive in perfect condition.

Flexibond Tapes is one of the most prominent Strapping Patti Manufacturers in India, which offers high-quality strapping solutions that provide maximum protection for your products. From polypropylene to polyester and steel strapping, it has a lot of options in line with the requirements of clients.

In today’s competitive market, secure packaging is no longer just about products but now the safety of your worker, compliance with industry standards, and the trust that your customers place in your products. Invest in top quality strapping patti to ensure that your goods would be secured, protected, and intact during the process from beginning to end.

Contact Us

For more info about our strapping patti solutions, or to inquire about our products, please contact Flexibond Tapes today. We here are to be able to provide the best packaging solutions for your business.