Packaging plays a crucial role in ensuring that products reach their destination intact and secure. One of the most essential components of any packaging process is the cello tape, a versatile and reliable material that can be used for sealing boxes, bundling items, and even labeling. However, not all cello tapes are created equal, and selecting the right one can make a significant difference in your packaging’s effectiveness. In this blog, we will explore the key factors to consider when choosing the best cello tape for your packaging needs, with a particular focus on the offerings from Flexibond Tapes, a leading cello tape manufacturer in Gujarat, India.

1.Understand Your Packaging Requirements

The first step in choosing the right cello tape is understanding your specific packaging requirements. Consider the type of products you are packaging, the weight of the items, and the conditions they will be exposed to during transit. For instance, if you are packaging heavy items, you will need a strong, durable tape that can withstand the weight without breaking or tearing. On the other hand, for lighter packages, a standard tape may suffice.

2. Consider the Tape’s Adhesive Strength

The adhesive strength of the tape is one of the most critical factors to consider. A tape with strong adhesive will ensure that your packages remain securely sealed throughout their journey. FlexibondTapes, a renowned packing cello tape manufacturer in Gujarat, India, offers a range of tapes with varying adhesive strengths to cater to different packaging needs. Whether you need a tape for heavy-duty packaging or something more suitable for light and medium-weight packages, they have the right product for you.

3. Thickness and Durability

The thickness of the cello tape is another important factor. Thicker tapes generally offer better durability and are less likely to tear or break under pressure. However, they may also be more challenging to work with if you need a tape that can be easily cut or torn by hand. Flexibond Tapes provides tapes in various thicknesses, ensuring that you can find a product that balances durability and ease of use.

4. Tape Width

The width of the tape you choose should be appropriate for the size of your packages. Wider tapes offer better coverage and are ideal for sealing larger boxes, while narrower tapes are suitable for smaller packages. Using the correct tape width ensures that your packages are sealed efficiently without wasting tape.

5. Environmental Conditions

Consider the environmental conditions your packages will be exposed to during shipping and storage. If your packages will be subjected to extreme temperatures, moisture, or UV light, you will need a tape that is designed to withstand these conditions. Flexibond Tapes, a leading cello tape manufacturer in Gujarat, India, offers tapes that are specially formulated to resist environmental factors, ensuring that your packages remain secure regardless of the conditions.

6. Type of Cello Tape

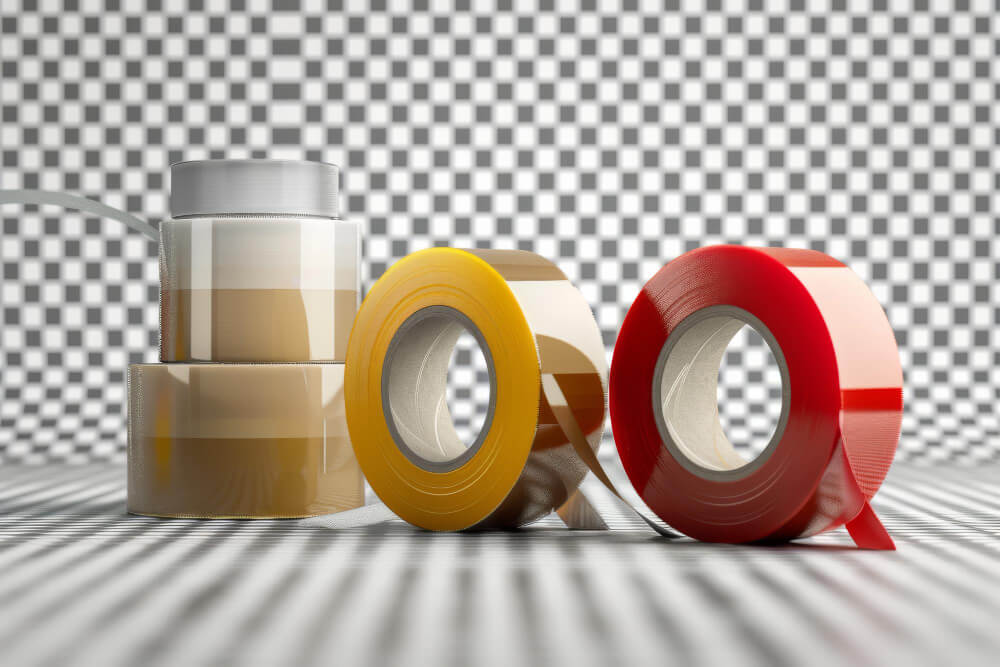

There are various types of cello tapes available, each suited for different applications. Some of the most common types include:

- Transparent Tape: Ideal for general-purpose packaging and when the appearance of the package is important.

- Brown Tape: Commonly used for sealing cardboard boxes, especially in industrial settings.

- Printed Tape: Useful for branding and labeling, as it can carry company logos or handling instructions.

- Double-Sided Tape: Suitable for bonding two surfaces together without the tape being visible.

By understanding the different types of tapes available, you can choose the one that best suits your packaging needs.

7. Brand Reputation

The reputation of the manufacturer is an essential consideration when choosing cello tape. A reputable brand is more likely to offer high-quality products that meet your packaging needs. Flexibond Tapes has established itself as a trusted name in the industry, known for producing reliable and durable packaging solutions. As a top packing cello tape manufacturer in Gujarat, India, their products are widely used by businesses across the country, reflecting their commitment to quality.

8. Cost-Effectiveness

While it is important to choose a high-quality tape, you should also consider the cost. The best cello tape for your packaging needs should offer a good balance between quality and affordability. Flexibond Tapes offers competitively priced tapes without compromising on quality, making them an excellent choice for businesses looking to optimize their packaging costs.

9. Ease of Use

The tape you choose should be easy to apply, whether manually or with a dispenser. A tape that is difficult to work with can slow down your packaging process and lead to inefficiencies. Look for tapes that are easy to unwind and cut, and that stick well without requiring excessive pressure. Flexibond Tapesdesigns its tapes with user-friendliness in mind, ensuring that they are easy to handle and apply, even in high-volume packaging environments.

10. Customizable Options

In today’s competitive market, branding is key. Customizable cello tapes can be a valuable tool for reinforcing your brand’s identity. Flexibond Tapes as a leading cello tape manufacturer in Gujarat, India, offers printed tapes that can be customized with your company’s logo, name, or any other branding elements. This not only helps in brand recognition but also adds a professional touch to your packaging.

11. Sustainability

With growing environmental concerns, it is important to consider the sustainability of your packaging materials. Eco-friendly cello tapes made from recyclable materials can help reduce your business’s environmental impact. Flexibond Tapes is committed to sustainability and offers eco-friendly tape options that do not compromise on quality or performance.

12. Testing and Feedback

Before making a final decision, it is advisable to test the tape in real-world conditions. Purchase samples of different tapes and use them on your packages to see how they perform during transit and storage. Gather feedback from your packaging team to understand the tape’s usability and effectiveness. This will help you make an informed decision that meets your specific packaging needs.

Conclusion

Choosing the best cello tape for your packaging needs involves considering various factors such as adhesive strength, thickness, environmental conditions, and ease of use. By selecting a high-quality tape from a reputable manufacturer like FlexibondTapes, a top cello tape manufacturer in Gujarat, India, you can ensure that your packages are securely sealed and protected during transit. Remember to balance quality with cost-effectiveness and consider the sustainability of your packaging materials. With the right cello tape, you can enhance the efficiency of your packaging process and ensure that your products arrive safely at their destination.

No comment yet, add your voice below!