When goods move from one place to another, strong packaging becomes very important. Boxes, cartons, and bundles need support so they do not break or open during transport. This is where strapping patti plays a big role. Choosing the right Strapping patti manufacturer in India helps businesses make sure their products stay safe from packing to delivery.If you are searching for a reliable manufacturer you can trust for heavy-duty packaging, Flexibond Industries is a strong name in the packaging industry. Businesses across different sectors choose Flexibond Industries because their strapping solutions are made for strength, safety, and long-term use. If you want dependable packaging materials for global supply needs, you should buy directly from Flexibond Industries by visiting their official website and connecting with their team.

What Is Strapping Patti and Why Is It Important?

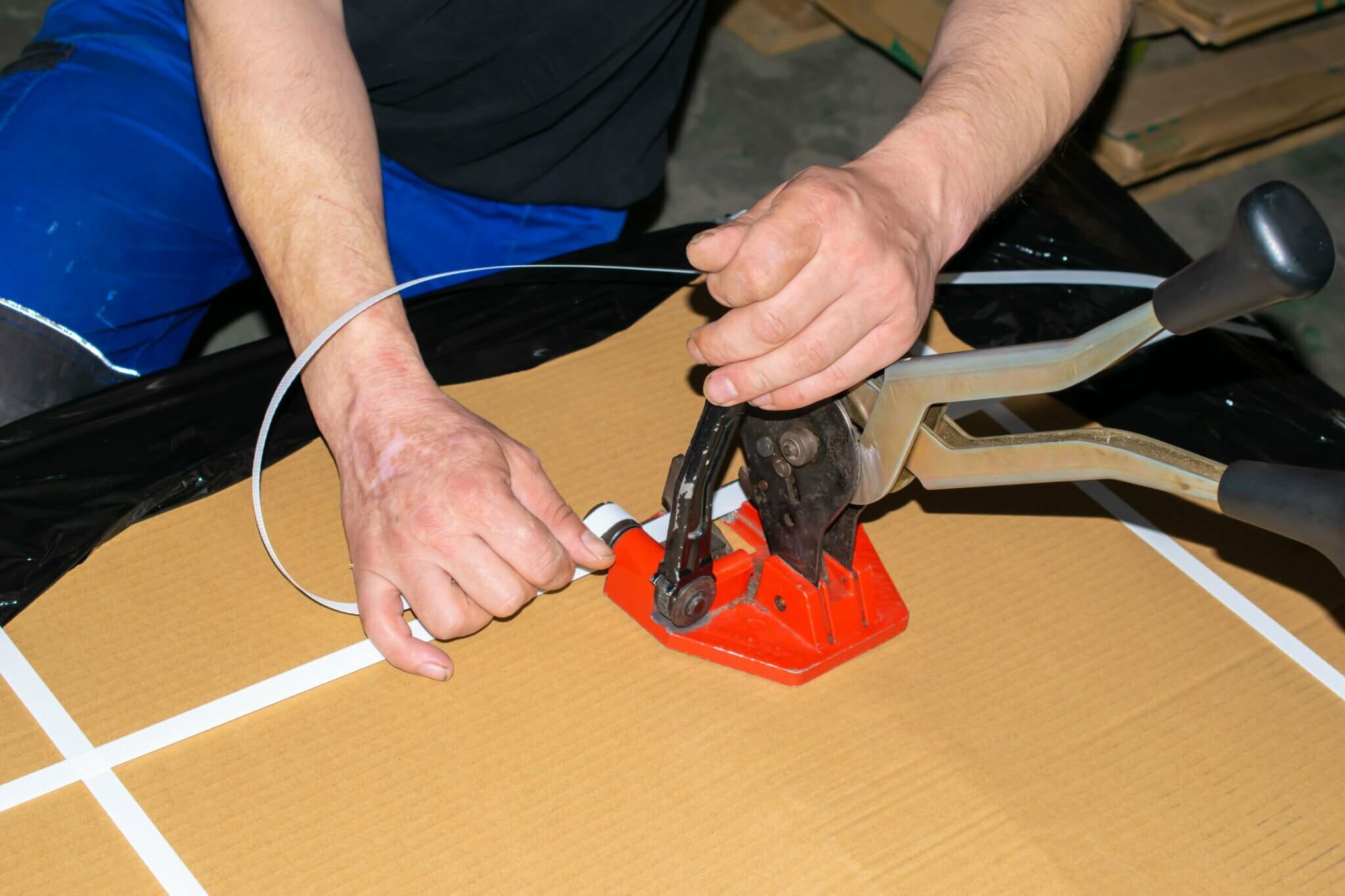

Strapping patti is used to tie, bundle, and secure goods. It holds cartons tightly so they do not shift during storage or transport. Without strong strapping, goods can fall, get damaged, or open before reaching the customer. A dependable Strapping patti manufacturer in India understands that different industries have different needs. Heavy boxes, stacked pallets, and export goods require strong and reliable strapping material. This is why quality matters more than anything else when selecting a manufacturer.

Why Manufacturer Selection Matters for Heavy-Duty Packaging

Not all strapping materials are the same. Some may look fine but fail under pressure. A trusted Strapping patti manufacturer in India focuses on consistency, strength, and performance. This reduces risk and gives peace of mind to businesses shipping goods locally or worldwide.

Manufacturers with proper systems and experience can deliver products that work well in real-world conditions. Flexibond Industries follows controlled production processes to ensure every roll of strapping patti meets industrial expectations.

Key Things to Look for in a Strapping Patti Manufacturer

1. Product Strength and Reliability

Strapping patti must hold weight without breaking or loosening. A reliable Strapping patti manufacturer in India uses tested materials and modern machines to ensure strength and durability. This is especially important for long transport routes and export shipments.

2. Manufacturing Experience

Experience brings understanding. Manufacturers who have worked with different industries know what works best in real conditions. Flexibond Industries has industry experience that helps them create strapping solutions suitable for heavy-duty use.

3. Quality Control Standards

Consistency is key in packaging. Every roll should perform the same way. A professional Strapping patti manufacturer in India maintains quality checks at every stage of production to avoid defects and variation.

4. Ability to Serve Different Industries

Different sectors like logistics, textiles, FMCG, construction, and manufacturing all use strapping in different ways. A good manufacturer understands these needs and delivers suitable solutions without confusion.

Why Flexibond Industries Is Trusted by Businesses

When businesses look for reliability, they choose manufacturers who focus on quality and long-term performance. Flexibond Industries is known for supplying strapping solutions that support heavy packaging needs without failure.Their focus on industrial packaging helps businesses reduce packaging problems and improve safety during handling and shipping. For companies that want a dependable supply partner, Flexibond Industries offers consistency and trust.If your business ships products across cities or countries, working with Flexibond Industries ensures your packaging process stays smooth and dependable.

Importance of Complete Packaging Support

Many businesses prefer suppliers who understand the full packaging process. Along with strapping solutions, companies often need other packaging materials to complete their operations. Working with a supplier that also understands related packaging products makes coordination easier.Some manufacturers also operate as a BOPP tape manufacturer in India, supporting carton sealing and branding needs. Others also work as a Masking tape manufacturer in India, helping with surface protection during production and finishing work. This wide understanding of packaging requirements helps businesses manage their operations better.

Simple Packaging Solutions for Global Use

Since packaging needs exist everywhere, strapping materials must work in different environments. Heat, cold, humidity, and long transport times all affect packaging performance. A professional Strapping patti manufacturer in India designs products that can perform reliably under different conditions. This is important for global businesses shipping goods to different countries. Consistent quality helps protect products no matter where they travel.

Why Long-Term Partnership Matters

Choosing a manufacturer is not just about today’s needs. It is about building a long-term relationship. A dependable manufacturer supports business growth by delivering stable quality and dependable service over time. Businesses that partner with Flexibond Industries benefit from manufacturing expertise, reliable supply, and packaging solutions designed for real use. This helps companies focus on their core work without worrying about packaging failures.

How the Right Manufacturer Improves Business Confidence

Strong packaging reduces damage, improves safety, and builds trust with customers. When products reach customers in good condition, it reflects positively on the brand. This is why selecting the right Strapping patti manufacturer in India plays a role in overall business success.Manufacturers who understand packaging challenges and provide reliable solutions help businesses operate smoothly across supply chains.

Making the Right Choice for Your Packaging Needs

Selecting the right Strapping patti manufacturer in India requires careful thought. Look for experience, product strength, quality systems, and industry understanding. A manufacturer that focuses on long-term performance will always be a better choice for heavy-duty packaging needs. Flexibond Industries continues to support businesses with strapping solutions made for strength and reliability. If you want packaging materials you can trust for local and global use, this is a manufacturer worth choosing. Contact us today