Home improvement projects can be a fantastic way to add a personal touch to your living space. If you’re looking for a versatile and cost-effective material to elevate your DIY projects, Strapping Patti is a great option. In this blog, we’ll explore creative ways to use strapping patti, highlight its benefits, and introduce you to Flexibond Industries Pvt Ltd, a leading strapping patti manufacturer in Gujarat and India.

What is Strapping Patti?

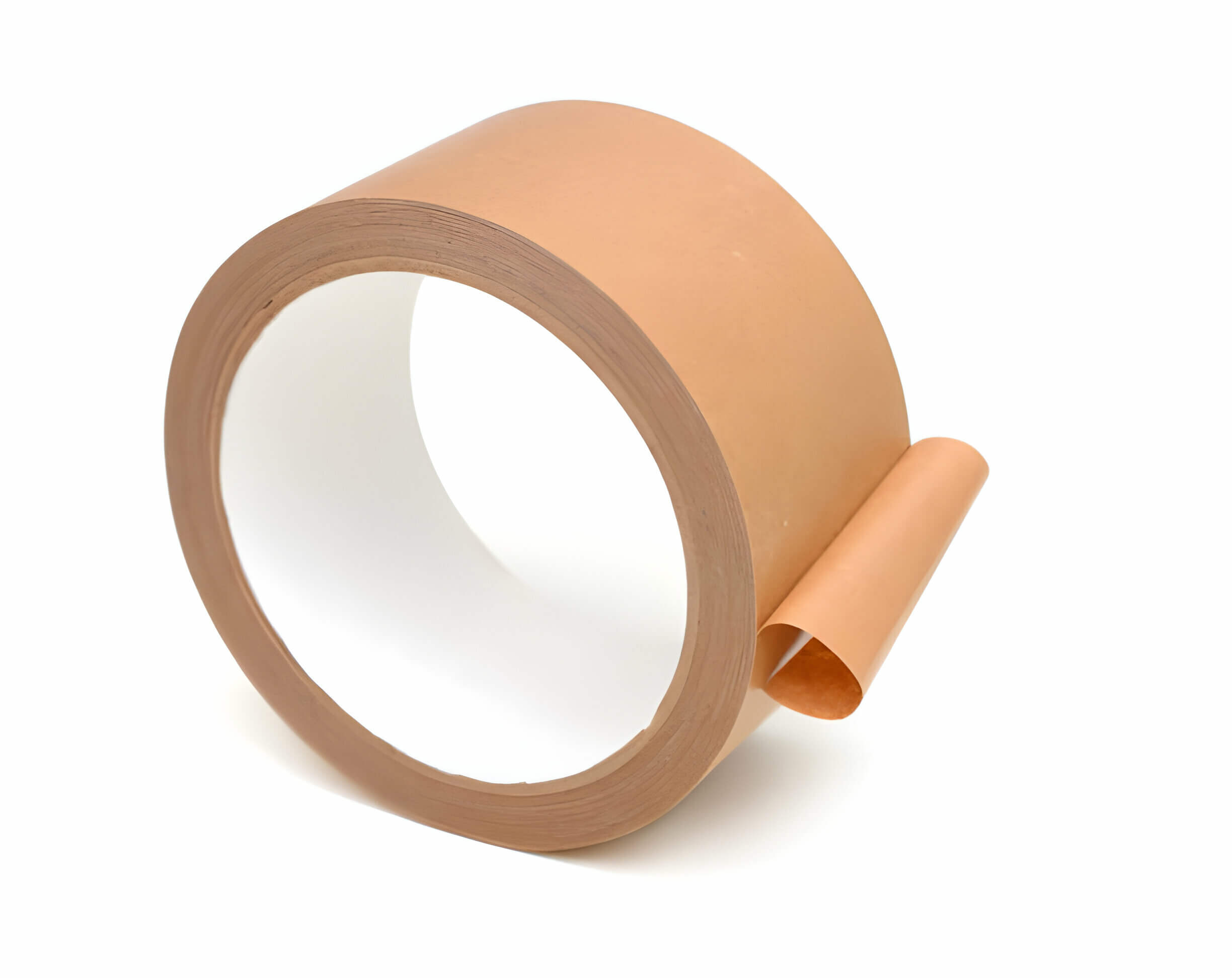

Strapping patti, also known as strapping tape or banding tape, is a type of durable plastic strip used for securing or bundling items together. It’s commonly used in packaging and shipping but has found a new role in the world of home improvement. Made from materials like polypropylene or polyester, strapping patti is known for its strength, flexibility, and ease of use.

Creative Uses for Strapping Patti in Home Improvement

- DIY Wall Art and Frames

One of the simplest ways to use strapping patti in your home decor is by creating custom wall art and picture frames. You can use the strapping patti to create geometric patterns or frames for your favorite photos. The durability of strapping patti ensures that your creations will stay intact and look stylish for years to come.

- Furniture Restoration

If you have old furniture that needs a facelift, strapping patti can be a handy tool. Use it to reinforce weak spots, create unique design accents, or even replace worn-out straps on chairs and tables. The flexibility of strapping patti makes it an excellent choice for furniture restoration projects.

- Home Organization Solutions

Strapping patti can help you keep your home organized. Use it to create custom storage solutions, such as organizing cords, bundling items together, or even crafting your own DIY storage bins. The strength and versatility of strapping patti make it ideal for various organizational tasks.

- Gardening and Outdoor Projects

For garden enthusiasts, strapping patti can be used to support plants, create garden trellises, or even build rustic outdoor furniture. Its resistance to weather conditions ensures that your garden projects remain sturdy and functional throughout the year.

- Creative Gift Wrapping

Add a personal touch to your gift-giving with strapping patti. Use it to create unique wrapping designs, add decorative elements, or even craft custom gift tags. The wide range of colors and styles available for strapping patti allows you to match it perfectly with any occasion.

Benefits of Using Strapping Patti

- Durability and Strength

Strapping patti is known for its strength and durability. It can withstand significant pressure and is resistant to tearing, making it ideal for various DIY projects that require reliable materials.

- Flexibility and Versatility

The flexibility of strapping patti allows it to be used in a wide range of applications. Whether you’re working on a home improvement project or a creative craft, strapping patti can adapt to your needs and provide a strong hold.

- Cost-Effective Solution

Compared to other materials, strapping patti is an affordable option for DIY enthusiasts. Its low cost makes it a budget-friendly choice for various home improvement projects without compromising on quality.

- Ease of Use

Strapping patti is easy to work with and doesn’t require special tools or skills. You can easily cut, shape, and apply it to your projects, making it an accessible option for both beginners and experienced DIYers.

Choosing the Right Strapping Patti Manufacturer

When selecting strapping patti for your projects, it’s essential to choose a reputable manufacturer. Flexibond Tape is a prominent strapping patti manufacturer in Gujarat and India known for their high-quality products. Their strapping patti comes in various sizes, colors, and strengths, ensuring that you find the perfect match for your DIY needs.

Flexibond Industries Pvt Ltd is committed to delivering reliable and durable strapping patti that meets the highest industry standards. By choosing their products, you can be confident that you’re using a superior material for your home improvement projects.

Conclusion

Strapping patti is a versatile and cost-effective material that can enhance your DIY home improvement projects. From creating custom wall art to organizing your home and supporting your garden, strapping patti offers numerous creative solutions. With its durability, flexibility, and affordability, it’s an excellent choice for any DIY enthusiast.

When looking for high-quality strapping patti, consider Flexibond Industries Pvt Ltd, a leading strapping patti manufacturer in Gujarat and India. Their commitment to quality ensures that you’ll have the best materials for your creative endeavors. So, get inspired, gather your strapping patti, and start transforming your home with innovative DIY projects!