Organization matters in almost every sphere of life-home, office or business operation. By making use of one such tool like adhesive tape, organized living can be achieved. With the diverse options available in the world of tapes, most people use cello tape. Whether it is packing or organizing, labeling or crafting, cello tape has become a must-have item. But does this automatically mean that the Cello Tape Manufacturer in Gujarat can help you organize? Let’s find out while exploring how choosing the right manufacturer, like Flexibond Tapes, makes all the difference in your organization efforts.

Importance of Cello Tape in Staying Organized

Translucent adhesive tape, popularly known as cello tape, is used everywhere-be it to wrap gifts, seal packages, mark products, or temporarily fix anything. The fact that it is translucent and pretty strong makes it a favorite tape for both commercial and domestic use. Here’s how a quality cello tape can be of help in staying organized:

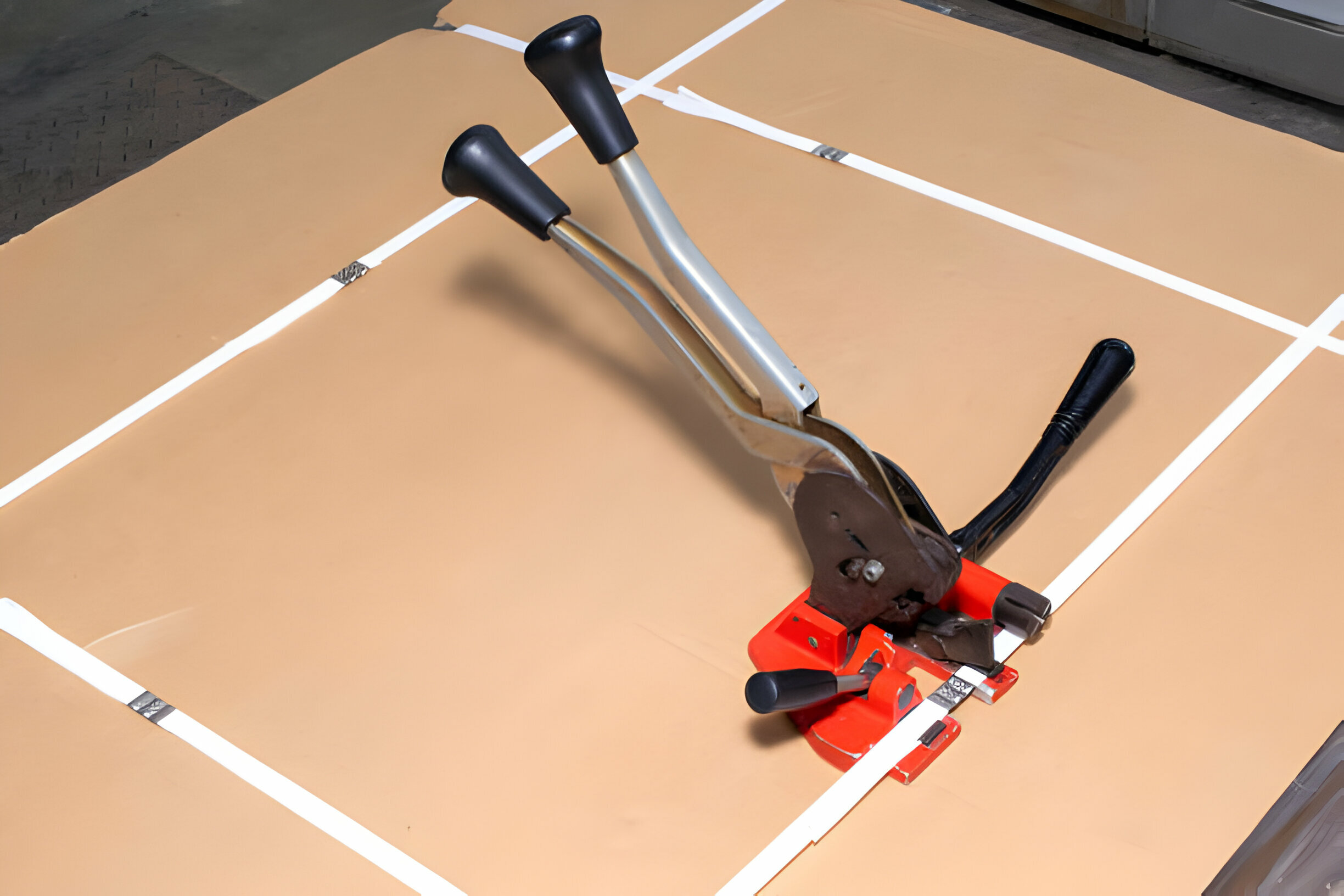

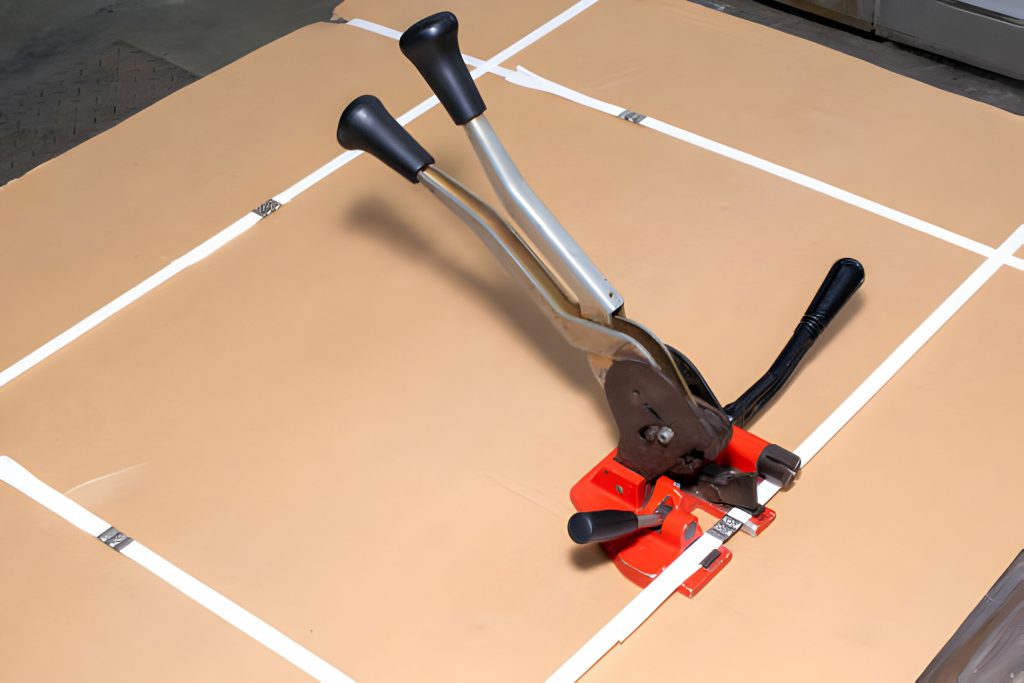

- Efficient Packaging

Whenever you have to relocate or shift stuff, sealing the boxes is a definite requirement with cello tape. It can protect fragile items, and it ensures your storage boxes do not open up, providing the dependable adhesion that you require. Since a Cello Tape Manufacturer in Gujarat provides the best quality cello tapes, such tapes ensure durability and extended usage so that packing items may be done in a structured and organized manner. - Labeling and Sorting

Labeling is one of the easiest ways to get organized, especially in workspaces or storage areas. Cello tape is perfect for sticking labels on boxes, files, or any other items that require sorting. They make neat and professional-looking arrangements, thus making it easier to find what is needed. Whether in a home office, warehouse, or retail store, quality cello tape makes labeling easy to do. - Crafting and DIY Hobby

The need to be creative and stay organised has made crafting a hobby for many. This could be in the form of scrapbook or greeting cards organisation or even making a personal label for jars and containers. For all such DIY enthusiasts, cello tape forms an essential thing. A Cello Tape Manufacturer in Gujarat realizes that every creative artist has unique requirements and thus offers cello tapes of various widths and finishes according to diverse requirements.

Use of cello tape is a very simple yet very effective way to stay organized. Be it marking due dates on your calendar, creating reminder boards, or sticking motivational quotes in visible places; it all helps to keep a better life-organized routine. Quality tape ensures that your schedule remains steadfast without the disruption caused by loose papers and disorganization of schedules.

Why choose a Cello Tape Manufacturer in Gujarat?

A Cello Tape Manufacturer in Gujarat will always give a prominent place to quality and reliability of the product. The manufacturing industry in Gujarat is very robust, and this ensures that selecting a manufacturer from this region always guarantees excellent products at best competitive prices. Some reasons why sourcing from a Cello Tape Manufacturer in Gujarat can make all the difference:

This is because a quality manufacturer, like Flexibond Tapes, understands the importance of ensuring adhesion properties in cello tapes. Low-quality adhesion means frustration because most of the time, the tapes fail to adhere where you need it most. With a proven manufacturer in Gujarat, rest assured that your cello tapes will offer the right amount of adhesion to help arrange a working space or your home/office perfectly.

- Durability and Reliability

Since Cello tapes are always put to exposure with varying temperature, humidity, and handling conditions, it forms a demand for a reliable Cello Tape Manufacturer in Gujarat who would ensure that the tapes are made to withstand these conditions; they should give long-lasting performances. This durability becomes a core necessity in both commercial and personal applications where the tapes may have to face tough handling. - Cost-Effective Manufacture

Gujarat is one of the most cost-efficient manufacturing hubs in the world, whereby you can always source cheap, high-quality cello tapes without compromise. When working with a Cello Tape Manufacturer in Gujarat, you get value for money in the sense of quality product delivery at reasonably good rates. If you need cello tapes in large quantities or just a few rolls, manufacturers in Gujarat can accommodate flexible pricing.

From clear tapes to colored tapes and special finishes like glossy or matte, the top Cello Tape Manufacturers in Gujarat, like Flexibond Tapes, provide you with all options to stay organized in your preferred manner.

How Flexibond Tapes May Make Your Process of Organization Easier

Flexibond Tapes stands high among some of the tallest leading cello tape manufacturing companies in Gujarat. Known for quality and versatile adhesive products, Flexibond Tapes has been helping businesses and individuals stay organized for years. Here’s how they can assist you in living an organized life.

- Customizable Solutions

Find cello tapes at Flexibond Tapes which can be customized according to your requirements. The sizes, colors, and designs for the tapes vary, which makes them suitable for any kind of packaging, labeling, or office organization. If you have a business, you can even request custom branding on the tape so that the packages will stand out with being sealed securely. - Reliability for Commercial Use

For business, especially e-commerce and shipping, packaging and sealing the items in a really safe and secure manner is very important. Flexibond Tapes offers you tapes that are strong enough to ensure packages are sealed securely before they are shipped out. They are indeed designed for commercial environments where volume and speed can go a long way, but quality has never been compromised. - Creativity and Organization

Often, to be better organized one needs some creativity. Flexibond Tapes support the creativity because the solutions offered in tapes solutions provide the transparent cello tapes ideal for use as clear professional labels, and this besides a variety of other decorative tapes to let the consumers be as creative as they can. Flexibond Tapes let consumers be as organized as they want to. - Eco Friendly

Flexibond Tapes boasts of cello tape variants that are eco-friendly. That said, you can hold on to all efforts of making life organized while staying clear of hurt from the other side of the earth. Tapes in themselves will be made from non-hazardous materials that lead to less waste and pollution. These are also the responsible ways through which you can keep your home and business organized.

How Cello Tape Can Help You Organize in Different Environments

Let’s take a closer look at how cello tapes can be applied to organize in different environments:

- Organization in the home

Whether you’re organizing your closet, the kitchen, or setting up a study area, cello tape can help you remain organized in the house. The use of cello tape might be in attaching labels to storage boxes and also sealing food packets and cables neatly. Cello tapes can keep everything in its place, reduce clutter, and make living more efficient. - Office Organization

Offices, especially busy ones, can become messy within a few days. Cello tape helps seal files, bind important documents together, and mark folders for easy referencing. Adhesive tape also proves useful when organizing office supplies such as pens, markers, among other small tools. - Retail and Packaging

Cello tape is a goldmine for any retail or e-commerce business because it ensures safe product packaging so that when these products reach their destinations, they are not damaged. Flexibond Tapes is the best Cello Tape manufacturer in Gujarat, which assures products reliable for common applications in commercial use. This makes it easier for businesses to maintain professionalism in the most sought after elements of packaging and organization.

Conclusion

Be it an office, a home, or a business, cello tape helps you stay organized in a more efficient manner. Partnership of a reliable Cello Tape Manufacturer in Gujarat with Flexibond Tapes assures high-quality, durable, and cost-effective tape solutions. With options of customization, reliability, and eco-friendly choices available, Flexibond Tapes has everything you would possibly need to keep you organized in every part of your life. Thus, the next time you think of organizing your space, think of the power of cello tape and the quality offered by leading manufacturers in Gujarat.