In today’s fast-paced business environment, the importance of efficient and sustainable packaging cannot be overstated. Companies are constantly seeking solutions that help them reduce waste, improve operational efficiency, and maintain the safety and stability of their shipments. One of the most effective tools to achieve this is stretch film, a versatile packaging material that has become a staple across industries. Stretch film not only secures products during transport and storage but also helps businesses reduce the overall usage of additional packaging materials, making it both a practical and eco-friendly choice. For those searching for a reliable Stretch film manufacturer in India, Flexibond Industries stands out as a trusted partner. Their high-quality stretch films are specifically designed to minimize packaging waste, protect products effectively, and improve the overall efficiency of packaging operations. Businesses looking for strong, durable, and professional-grade packaging solutions should consider purchasing directly from Flexibond Industries,and their website provides a comprehensive overview of available products and expert support for tailored packaging solutions.

What Is Stretch Film and Why It Matters

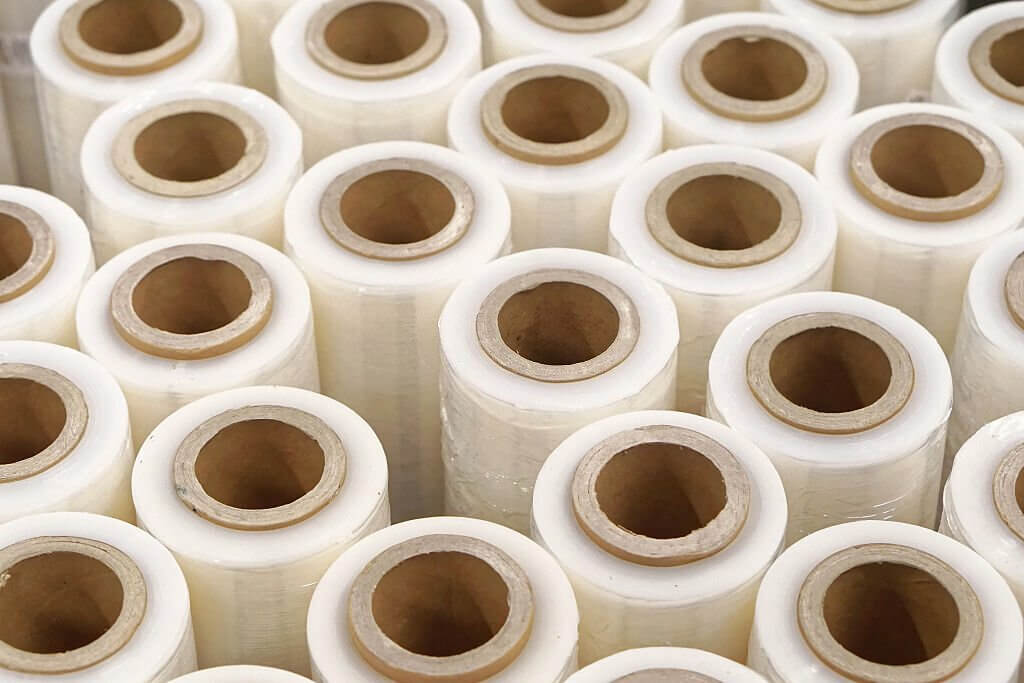

Stretch film is a highly stretchable plastic material that wraps tightly around products, pallets, or bundles. Its elasticity enables it to cling firmly to surfaces, keeping items secure and stable during transportation and storage. The right stretch film reduces the need for multiple layers of cartons or excessive adhesive tapes, ultimately minimizing waste while ensuring products remain intact. A reputable Stretch film manufacturer in India guarantees that each roll has consistent thickness, optimal cling properties, and superior durability. Without proper quality control, substandard films can tear easily, cause product movement, or require excessive material, which not only increases costs but also contributes negatively to the environment. High-quality stretch film ensures smooth operations, effective protection, and responsible use of materials, making it an essential part of modern packaging.

How Stretch Film Reduces Packaging Waste

Using high-quality stretch film can dramatically reduce packaging waste in several ways. Firstly, it allows businesses to wrap items securely using less material. A trusted Stretch film manufacturer in India produces films that are thin yet strong, ensuring products remain protected without unnecessary plastic use. Additionally, certain stretch films are designed to be reusable, meaning pallets can be wrapped and unwrapped multiple times, further reducing the total volume of film consumed. Stretch film also minimizes the need for additional adhesives or strapping, which can decrease reliance on products from a Cello tape manufacturer in India, as the film itself holds packages tightly together. By securing items effectively with fewer layers, businesses cut down on waste while simplifying their packing process. This not only saves operational costs but also contributes to environmentally sustainable practices, helping companies meet their green packaging goals.

How Stretch Film Improves Packaging Efficiency

Stretch film significantly enhances packaging efficiency, primarily by streamlining the wrapping process. Whether applied manually or through automated wrapping machines, stretch film can save considerable time compared to using multiple tapes or bulky packing materials. A dependable Stretch film manufacturer in India ensures that their films are compatible with both manual and machine wrapping systems, providing versatility for various packing operations. Beyond speed, stretch film stabilizes products during transport, reducing the likelihood of damage, loss, or the need for repacking. Its flexibility allows it to conform to various shapes and sizes, making it suitable for both small cartons and large pallets. Additionally, by consolidating materials and tightly bundling packages, stretch film helps maintain a tidy and organized storage area, improving warehouse management and overall operational flow.

Types of Stretch Films Offered by Manufacturers

Professional Stretch film manufacturers in India offer a wide variety of films to cater to the specific requirements of different industries. Hand stretch film is ideal for small-scale or manual wrapping operations, allowing workers to apply it efficiently and control tension. Machine stretch films are designed for automated wrapping systems, enabling rapid and consistent application for high-volume shipments. Pre-stretch films provide exceptional elasticity, which reduces material usage while maintaining the secure wrapping of heavy loads. Additionally, some manufacturers provide colored or printed stretch films, which serve the dual purpose of securing items while offering branding, inventory identification, or security markings. By selecting the right type of stretch film from a reputable manufacturer, businesses can maximize efficiency, ensure safety, and minimize unnecessary material consumption.

How Stretch Film Complements Other Packaging Materials

While stretch film is a versatile and effective solution, some packaging scenarios still require the use of adhesive tapes or other materials. Partnering with a reliable Cello tape manufacturer in India can provide complementary products for securing items that do not conform to standard pallets or require extra reinforcement. Using stretch film in combination with high-quality tapes ensures packages are thoroughly protected without excessive material usage. This approach balances efficiency and security, reducing waste while maintaining professional and reliable packaging. Stretch film’s adaptability allows it to serve as the primary securing material, with tapes providing support where necessary, creating an optimal packaging solution.

Sustainability Benefits of Using Stretch Film

In an era of increasing environmental awareness, businesses are under pressure to adopt sustainable practices. High-quality stretch films help companies reduce plastic usage by offering strong, thin films that maintain performance while consuming less material. By replacing excessive cardboard, tapes, or strapping, stretch film significantly decreases packaging waste. Furthermore, its efficiency reduces the overall carbon footprint associated with packaging, as less material is produced, transported, and discarded. Working with a trusted Stretch film manufacturer in India like Flexibond Industries ensures that eco-friendly options are available without compromising strength, durability, or ease of use. These sustainable practices not only benefit the environment but also enhance a company’s reputation as a responsible business.

Industries That Benefit From Stretch Film

Stretch film is a versatile solution adopted across a wide range of industries due to its ability to protect products while minimizing waste. In e-commerce and retail, it secures packages for shipping and reduces the reliance on cartons and tapes. The food and beverage industry benefits from stretch film’s ability to protect pallets from dust, moisture, and contamination. Pharmaceutical companies use stretch film to maintain the integrity of sensitive products during transport. Textile and apparel industries rely on stretch film to bundle large shipments efficiently while keeping waste to a minimum. In manufacturing and industrial goods, stretch film secures heavy pallets, facilitating better warehouse handling and safer shipping. By selecting the right Stretch film manufacturer in India, businesses can ensure that they choose films suitable for their industry-specific needs.

Tips for Maximizing Efficiency with Stretch Film

To achieve the maximum benefits of stretch film, businesses must focus on correct selection and application. Choosing the appropriate type of film, whether hand wrap, machine wrap, or pre-stretch, is essential to reduce waste and ensure stability. Proper application techniques, such as maintaining the correct tension and wrapping pattern, improve load stability and minimize material use. Stretch film can be effectively combined with minimal tape or strapping only when required, ensuring optimal protection without overuse. Storing stretch films in a cool, dry environment preserves their elasticity and adhesive properties. Additionally, training staff in the correct handling and wrapping methods significantly reduces waste and increases efficiency. Following these practices ensures that stretch film contributes fully to both operational and environmental goals.

How Flexibond Industries Supports Efficient Packaging

Flexibond Industries is a leading Stretch film manufacturer in India known for providing high-quality films that enhance efficiency and reduce packaging waste. Their products are designed to be compatible with both manual and machine wrapping systems, allowing businesses to streamline their packaging operations. Flexibond Industries also provides expert guidance, helping companies combine stretch film with products from a Cello tape manufacturer in India when additional security is necessary. By offering solutions tailored to various industries, Flexibond Industries ensures that businesses can protect their products, reduce material usage, and maintain professional packaging standards.

Long-Term Benefits of Using Stretch Film

Investing in high-quality stretch film from a reliable manufacturer brings long-term advantages. It reduces operational costs by lowering material usage and speeding up packing processes. Products remain stable during storage and transportation, minimizing damage and loss. The use of stretch film also demonstrates a commitment to environmental responsibility by reducing packaging waste. Overall, warehouse operations become more streamlined as fewer materials are needed, storage is more organized, and packing processes are more efficient. Partnering with a dependable Stretch film manufacturer in India ensures these benefits are consistently realized, improving both profitability and sustainability.

Choosing the Right Manufacturer

Selecting the right Stretch film manufacturer in India is crucial for businesses seeking efficiency and sustainability in their packaging operations. Companies should consider manufacturers that offer consistent quality, durability, and reliable performance across every roll of film. It is important to work with a manufacturer that provides compatibility with both manual and machine wrapping systems, as this ensures smooth operations regardless of your equipment. Offering a variety of film types, including hand wrap, machine wrap, pre-stretch, and colored options, is essential to meet diverse packaging needs. Sustainability and eco-friendly options are also key factors, as modern businesses aim to reduce environmental impact without compromising protection. Access to expert advice and industry-specific recommendations further enhances the value of the partnership. Flexibond Industries meets all these criteria, providing high-quality stretch films that improve efficiency, reduce waste, and support sustainable business practices.

Final Thoughts

Efficient and sustainable packaging is no longer optional; it has become a business necessity. Stretch film is a powerful tool that reduces material usage, secures shipments, and enhances operational efficiency. Companies that invest in high-quality films from a reliable Stretch film manufacturer in India benefit from improved packaging performance, reduced waste, and a stronger professional image. Flexibond Industries stands out as a trusted partner in this space, offering a wide range of films and expert guidance to help businesses achieve optimal packaging solutions. By combining stretch film with complementary products like those from a Cello tape manufacturer in India, businesses can ensure maximum protection and efficiency for all their shipments. Contact us today to learn more about our stretch film packaging solutions.